Leading technological breakthroughs in material development, computational design, and roll-to-roll additive manufacturing.

Microscopic Geometries, Manufactured at Scale

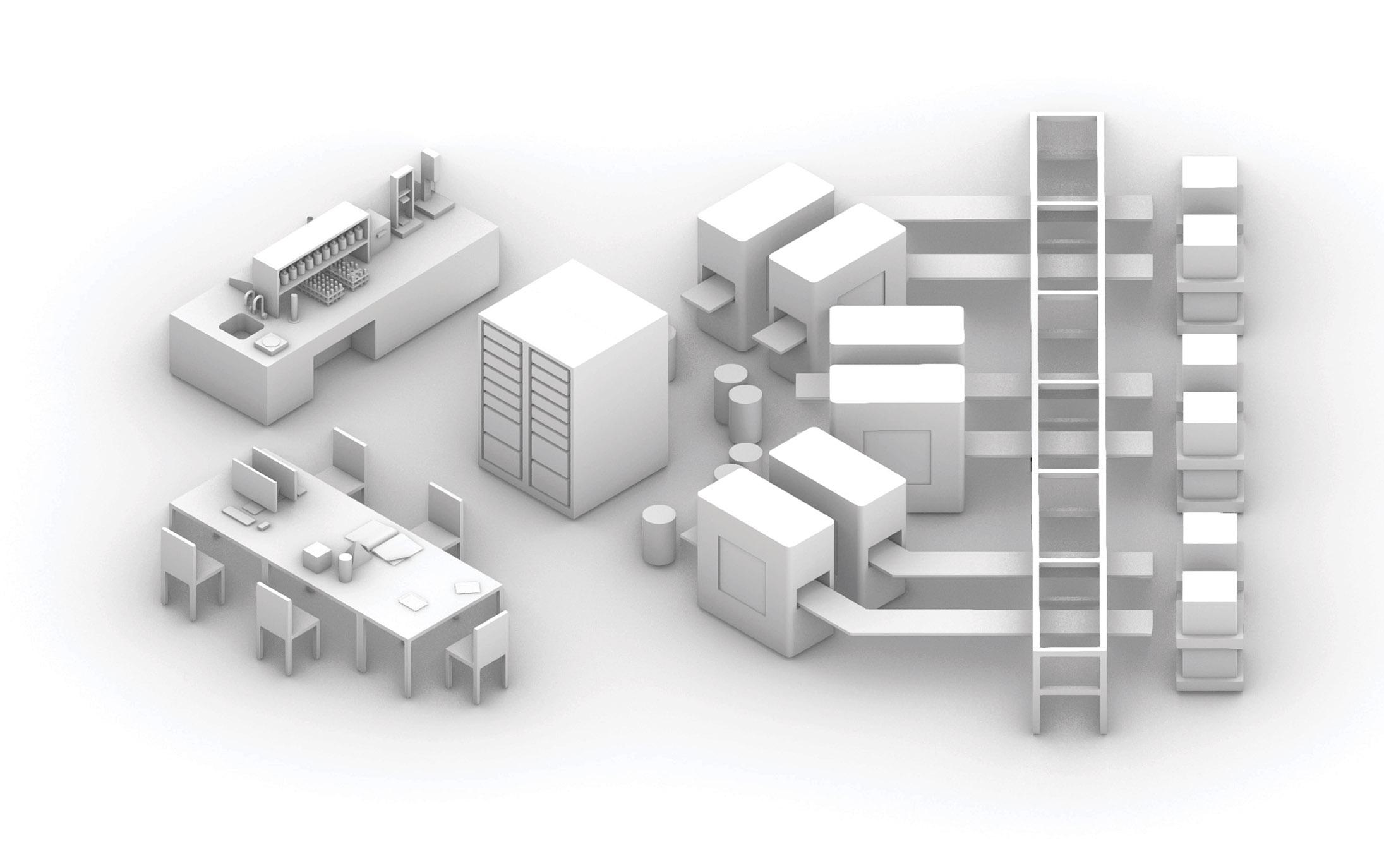

Technology

Material Development

We offer a range of proprietary materials optimized for precision manufacturing. Our formulations are developed by our in-house chemistry lab and tailored to meet our customer’s specifications for a range of commercial uses.

. Customized materials for unique product performance

.

. Materials engineered to meet regulatory and compliance needs

.

. Streamlined material development for faster market entry

Computational Design

Our state-of-the-art design software allows customers to visualize, simulate and digitally prototype products by adjusting parameters to achieve the ideal aesthetic and performance. These capabilities accelerate physical prototype iterations dramatically reducing overall time-to-market.

. Rapid generation of hundreds of design options without manual edits

.

. Data-driven simulations to compare and select the best designs

.

. Enhanced design accuracy for optimized product performance

Roll-to-Roll Additive Manufacturing Fleet

RAMP™ is OPT's flagship digital manufacturing technology and the world's first roll-to-roll additive manufacturing platform. Our system unlocks a unique combination of high volume capabilities and incredible precision for fine features. The entire process can be automated for 24/7 continuous production.

. Precise control over fine geometric features

.

. Unlimited build size in length

.

. Flexible and scalable production volume