What the Covid-19 pandemic has taught us about the medical device supply chain

What the Covid-19 pandemic has taught us about the medical device supply chain

Looking Back at a Year and a Half of Supply Chain Issues.

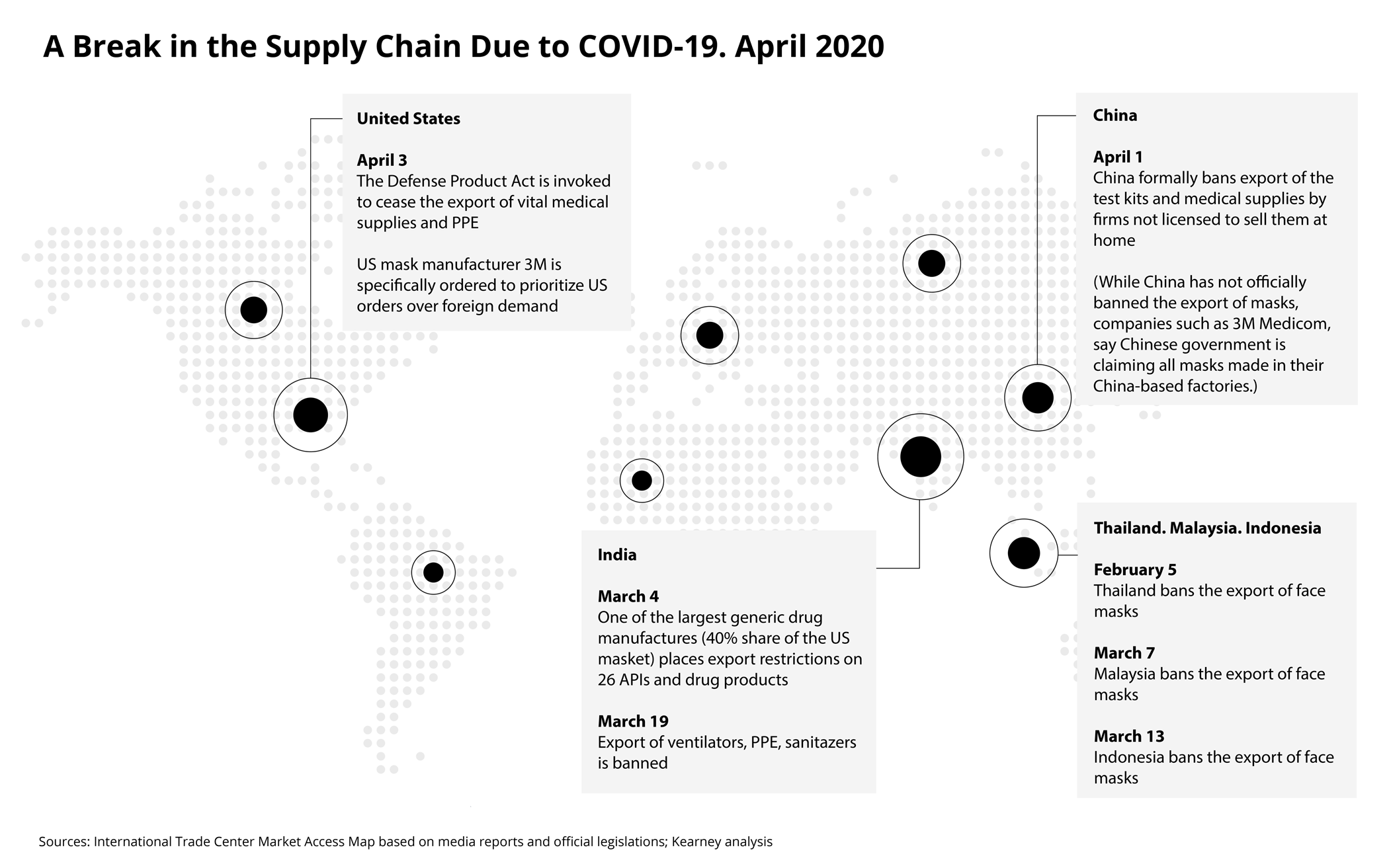

The COVID-19 pandemic has wreaked havoc on supply chains for products from semiconductors to toys. In the early days of the pandemic, manufacturers contended with stay-at-home orders and factory shutdowns. Many manufacturers are still working to catch up after these closures. Later in the year, an abnormal winter storm that led to power outages in Texas resulted in global shortages of refined oil products.1 Now, labor shortages are hampering the supply chain and companies are scrambling to find truck drivers, fulfilment center workers, and other people to keep the battered supply chain running.

Challenges and Solutions for the Medical Device Supply Chain

Though nearly every industry has been impacted by supply chain issues, the medical device industry has faced particularly difficult challenges. Supply chain problems for the medical industry are extremely high-stakes, especially in the early days of the pandemic. After all, these medical supplies, like masks and face shields, were needed to protect people from the virus before vaccines were available. A lack of protective equipment led to outbreaks and factory closures, along with other problems, which further contributed to supply chain chaos.

During this time, people found ways to alleviate medical device shortages with creativity, innovation, and collaboration. When hospitals were faced with shortages of supplies, many of them partnered with local companies which had the capacity to produce the much-needed materials, even if they were normally focused on different industries. Plastic furniture companies pivoted and started making face shields.2 Distilleries started making hand sanitizer.3

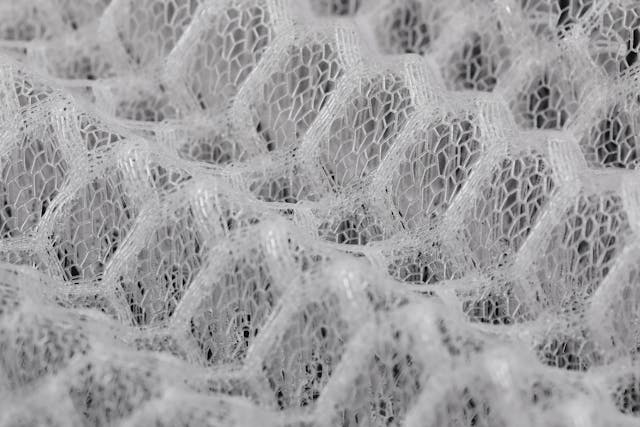

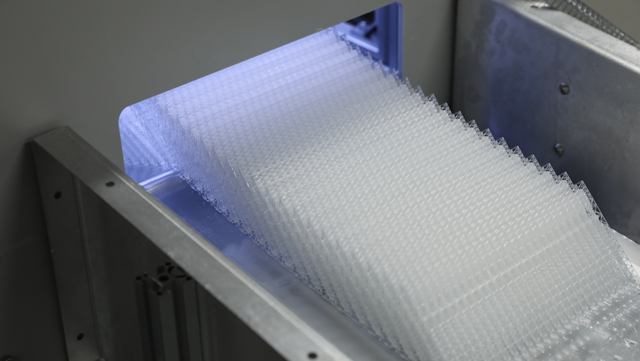

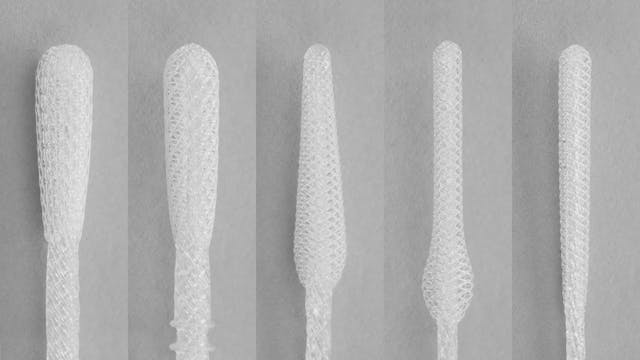

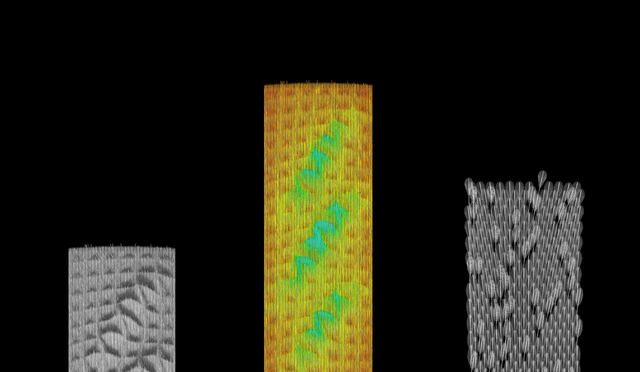

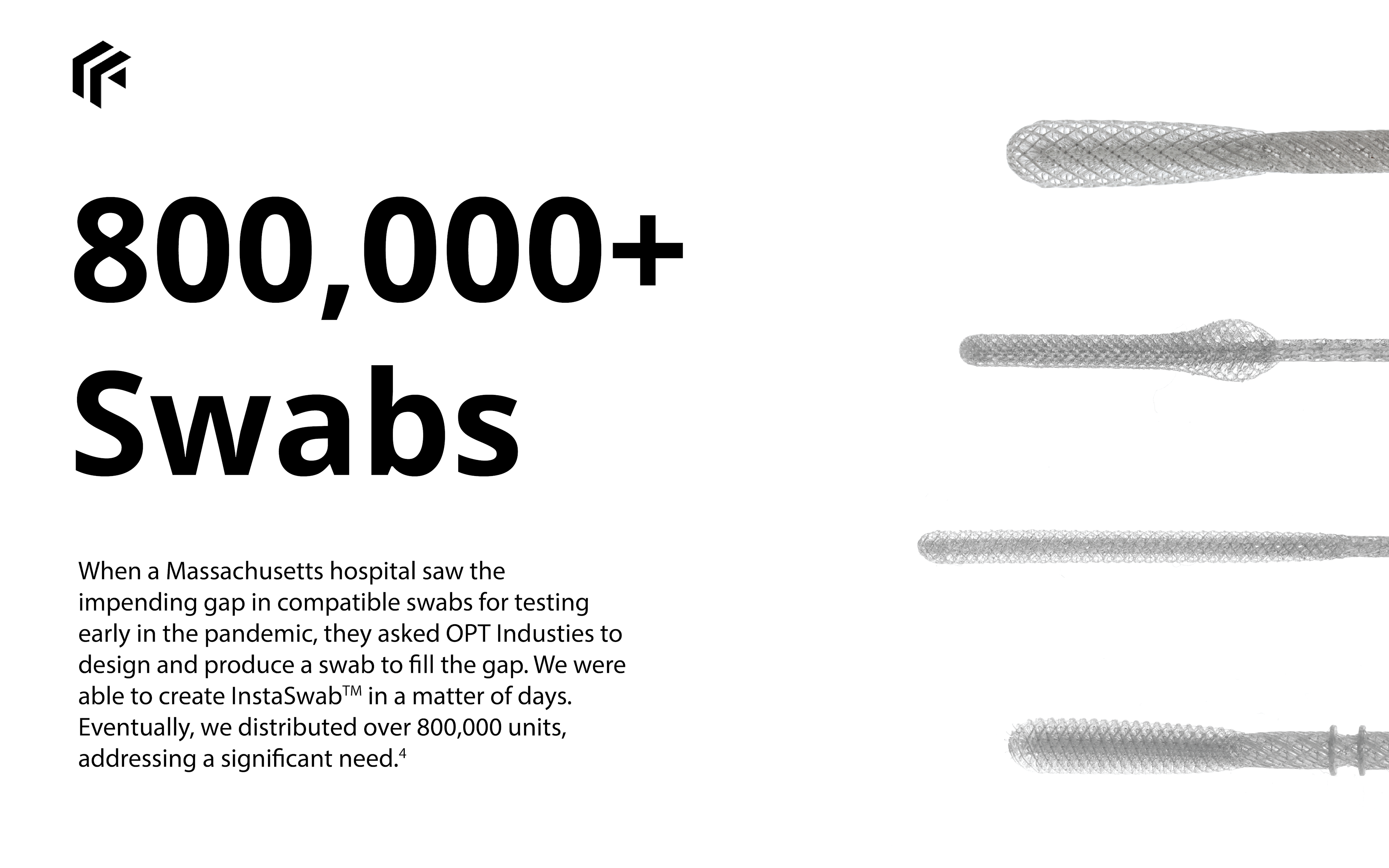

Ordinary people sewed face masks for frontline workers. At OPT, an important chapter of our own story began during this period. When a Massachusetts hospital saw the impending supply gap in compatible swabs for testing early in the pandemic, they asked us to design and produce a swab to fill the gap. We were able to create InstaSwabTM in a matter of days. So far, we distributed over 800,000 units, addressing a significant need.4 Though all the supply chain issues from the early days of the pandemic have not been completely solved, the situation is far better than it once was. Testing supplies, PPE, and other crucial products are more readily available now than they were at the onset of the pandemic. However, another surge in cases could result in more supply shortages.

Below is a table showing the types of medical devices which were in short supply early in the pandemic, why these shortages happened, and how they were alleviated:

Looking Ahead

Global supply chains are intricate and often fragile. Many industries did not realize just how fragile they were until the COVID-19 pandemic struck. The pandemic is not yet over. However, the medical device industry is already thinking through lessons learned over the past year and a half. Many companies are diversifying their supply chain, finding multiple options for sourcing materials and transporting products, to hedge against risk.7 Companies are also finding ways to be ready to ramp up deliveries in case of a spike in demand like the medical device industry experienced when the pandemic hit. Though COVID-19 was historic, it is likely not the last “force majeure” event of its kind. By learning from both the mistakes and successes of the past, we can create a more resilient supply chain and hopefully be more ready for the next time it is put to the test.

Bibliography

- Chaffin, Paul. “Building a Robust Medical Device Supply Chain.” Med, 23 Aug. 2021, https://www.med-technews.com/medtech-insights/medtech-materials-and-assembly-insights/building-a-robust-medical-device-supply-chain/.

- “3D-Printed Face Shields Can Protect Medical Staff from Coronavirus.” Dezeen, 4 Apr. 2020, https://www.dezeen.com/2020/03/27/3d-printed-face-shields-coronavirus-covid-19-masks-nagami-design/.

- “Distilleries Making Hand Sanitizer to Fight COVID-19.” Distilled Spirits Council of the United States, 3 Apr. 2020, https://www.distilledspirits.org/distillers-responding-to-covid-19/distilleries-making-hand-sanitizer/.

- “New Problems, New Solutions.” New Problems, New Solutions – Advanced Textiles Source, https://advancedtextilessource.com/2021/11/08/new-problems-new-solutions/.

- “Trump Invokes Defense Production Act for Ventilator Manufacturing.” CNBC, CNBC, 3 Apr. 2020, https://www.cnbc.com/2020/04/02/trump-invokes-defense-production-act-for-ventilator-manufacturing.html.

- “RADx.” National Institutes of Health, U.S. Department of Health and Human Services, https://www.nih.gov/research-training/medical-research-initiatives/radx.

- Chan, Edward, Chen, Peggy, Mulcahy, Andrew, Shelton, Shoshana, Qureshi, Nabeel “Medical Device Supply Chains An Overview and Description of Challenges During the COVID-19 Pandemic” RAND Health Care, September 2021